这部分内容是教如何使用聚酯树脂做标本的。这种树脂和上面的水晶滴胶是不同的。水晶滴胶和聚酯树脂都能用来做标本,但用聚酯树脂做出来的工艺简单效果更好但是切记要做好防护。因为我聚酯树脂是amazon上买的,并不是很清楚淘宝上的情况,想要购买这种树脂的各位可以去淘宝上找找看。

3.Polyester resin(聚酯树脂)

水晶滴胶都是双组份的操作不方便,而且制作过程中很难完全消除气泡(除非你用真空仓)。水晶滴胶在分层浇筑时会长生明显分层,不适合做全方位展示的标本。 但是水晶滴胶在时光宝石方面的应用非常突出。也就是说水晶滴胶适合用在浇筑很薄的东西时使用,不适合来塑封。

这里要介绍下这种树脂,这种树脂我在amazon上买的,这是wiki的英文介绍。

Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Polyester resins are used in sheet moulding compound, bulk moulding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass — so-called fiberglass reinforced plastic (FRP) — are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls.

Unsaturated polyesters are condensation polymers formed by the reaction of polyols (also known as polyhydric alcohols), organic compounds with multiple alcohol or hydroxy functional groups, with saturated or unsaturated dibasic acids. Typical polyols used are glycols such as ethylene glycol; acids used are phthalic acid and maleic acid. Water, a by-product of esterification reactions, is continuously removed, driving the reaction to completion. The use of unsaturated polyesters and additives such as styrene lowers the viscosity of the resin. The initially liquid resin is converted to a solid by cross-linking chains. This is done by creating free radicals at unsaturated bonds, which propagate in a chain reaction to other unsaturated bonds in adjacent molecules, linking them in the process. The initial free radicals are induced by adding a compound that easily decomposes into free radicals. This compound is usually and incorrectly known as the catalyst[citation needed] . Substances used are generally organic peroxides such as benzoyl peroxide or methyl ethyl ketone peroxide.

Polyester resins are thermosetting and, as with other resins, cure exothermically. The use of excessive catalyst can, therefore, cause charring or even ignition during the curing process. Excessive catalyst may also cause the product to fracture or form a rubbery material.

简单来说这种树脂就是单组份靠加催化剂固化的。具有高透的特点。而且只要自然放置气泡就会完全消失(做出来的成品基本是无气泡的)但是主要问题是这种树脂毒性很高。操作时要在通风环境下带手套进行,本人强烈建议若要使用这种树脂要带手套,护目镜防毒面具。

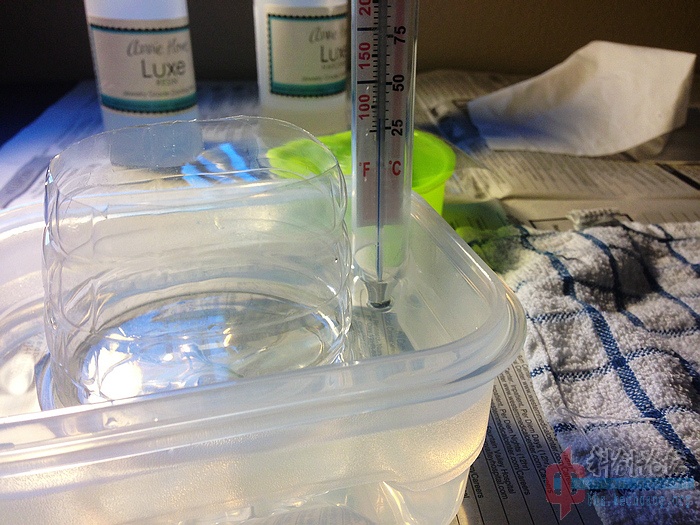

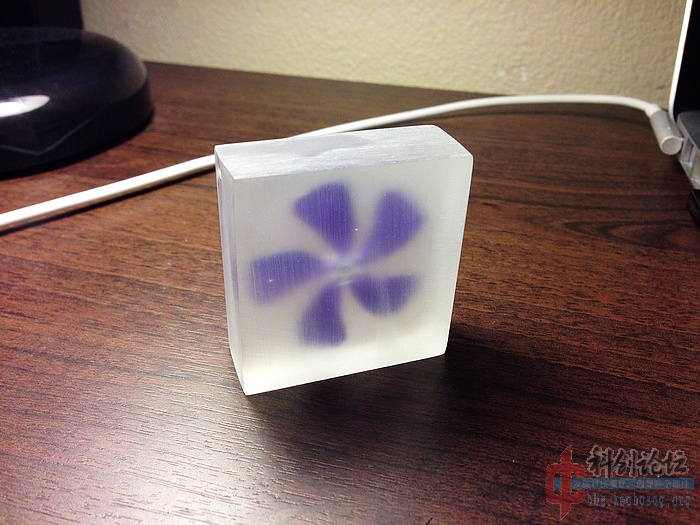

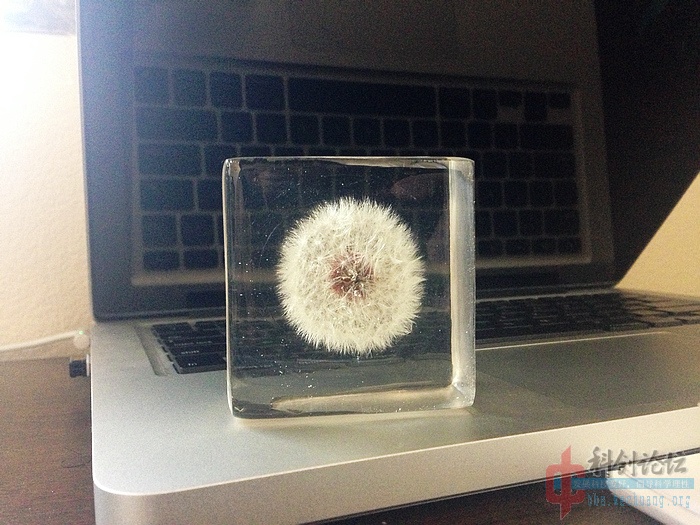

先上一张图来让大家明白下这种树脂的透明度

![1新型透明度_nEO_IMG.jpg]()

好了现在进入正题,如何使用这种Polyester resin做蒲公英及更大型的标本。

3.1 运用模块化制造标本

由于蒲公英的特殊性质导致接触到树脂后就不能在进行任何操作。这样的话对于做出个完美的标本是个很大的问题。所以我们要先将蒲公英预成型然后再将整个预成型的蒲公英浇筑成所要的形状。预成型的蒲公英是由树脂覆盖的。在进行最终浇筑时可以随便移动预成型的蒲公英到任意位置。可以根本性解决浇筑过程中蒲公英移位的问题

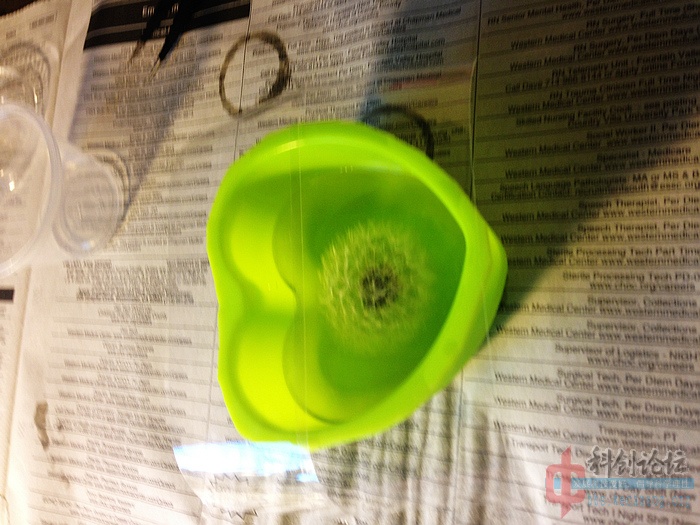

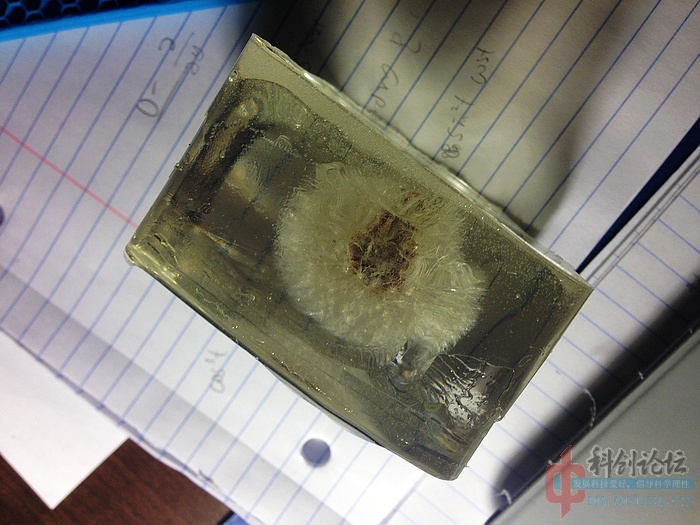

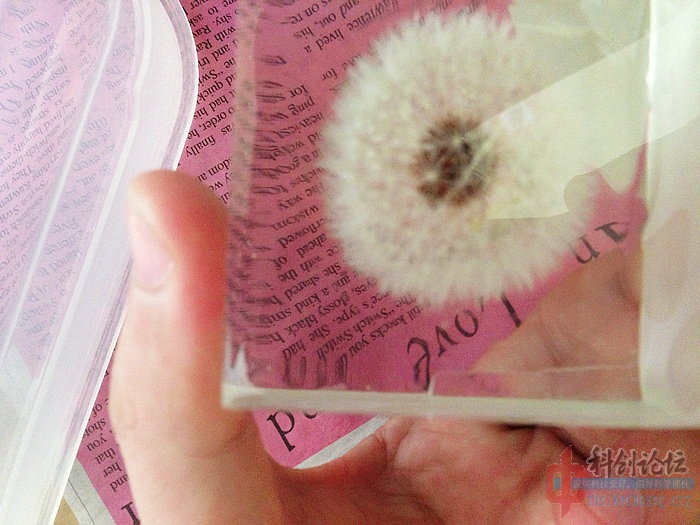

预成型的方法就是找个比实际要使用模具小的模具。(我这里用的是番茄酱的盒子)等配置好的树脂气泡完全消失后,将模具倒满树脂,一样让蒲公英自然沉降。位置问题可以完全不用担心。如果自然沉降后还有部分蒲公英在外面,就新配些浇筑,直到完全把蒲公英密封。等待完全硬化。

![2模块化_nEO_IMG.jpg]()

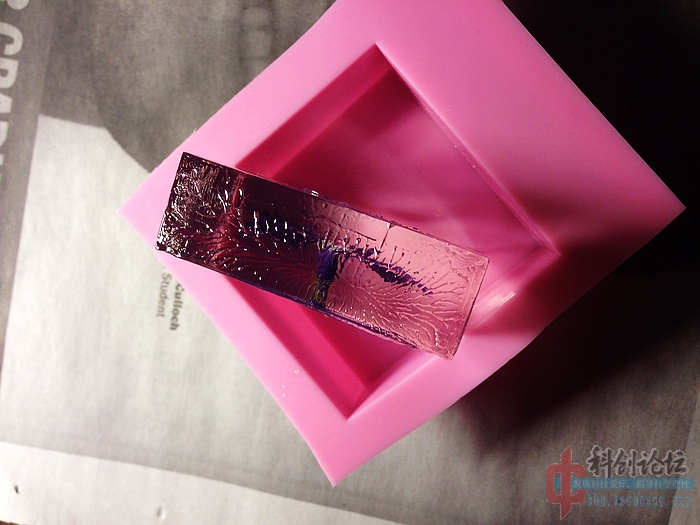

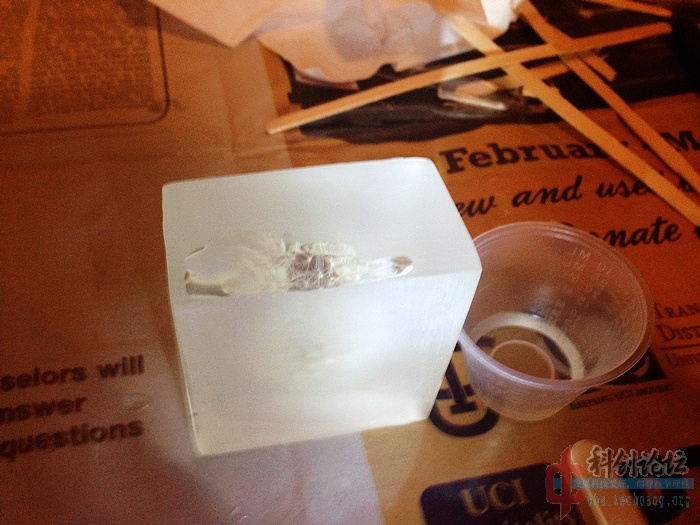

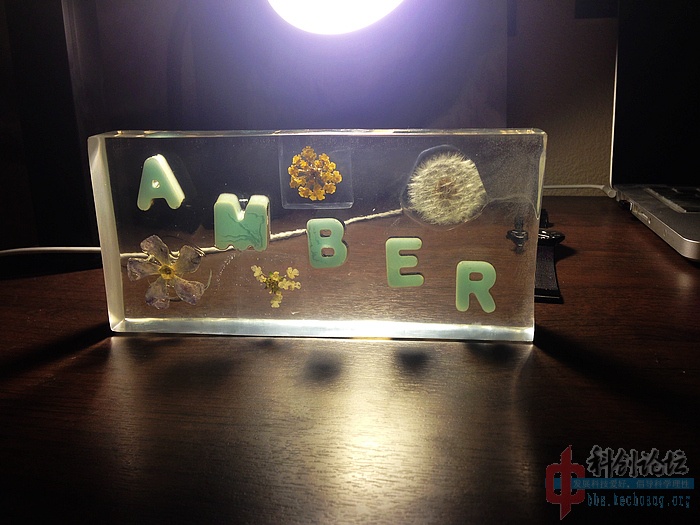

这时就得到了蒲公英模块,请对这个模块进行切削打磨,使其形状为正方体并且大小要尽可能的接近蒲公英的大小(这是我后来得出的经验,由于这个模块是在我发现打磨抛光技术前做的所以就没有切割,这也导致了一些问题)(正方体按我的经验是最合适的形状,大小和植株接近可以避免最终浇筑后的成品出现折射率不同的情况)

![4模块化_nEO_IMG.jpg]()

然后进行最终浇筑

用透明胶对模具进行清尘处理

![5磨具_nEO_IMG.jpg]()

![6清尘_nEO_IMG.jpg]()

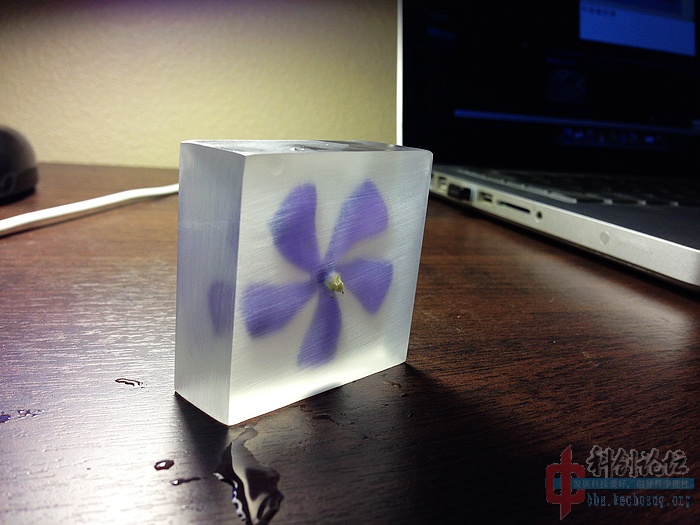

先将模具底层倒上一层薄薄的树脂,然后将预制模具在另一杯用来预浸润的树脂中浸润下。使预制模块底面沾满树脂,(这样可以大幅降低放入预制模块时长生气泡的概率)然后以一定角度缓慢放入模具中,这步一定要多加小心,如果发现预制模块和模具间有气泡就拿起来再放一次 ,等模块到位后,将整个模具填满(由于预制模块偏重,基本不会发生最终浇筑时上浮和移位的情况)将模具盖上...等待一个星期后脱模(一样强烈建议尽可能的久,这种树脂的硬化速度取决于催化剂的量和温度,但还是建议放的尽可能的久)

![9浇筑_nEO_IMG.jpg]()

![8粗成品_nEO_IMG.jpg]()

![7模块_nEO_IMG.jpg]()

3.Polyester resin(聚酯树脂)

水晶滴胶都是双组份的操作不方便,而且制作过程中很难完全消除气泡(除非你用真空仓)。水晶滴胶在分层浇筑时会长生明显分层,不适合做全方位展示的标本。 但是水晶滴胶在时光宝石方面的应用非常突出。也就是说水晶滴胶适合用在浇筑很薄的东西时使用,不适合来塑封。

这里要介绍下这种树脂,这种树脂我在amazon上买的,这是wiki的英文介绍。

Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Polyester resins are used in sheet moulding compound, bulk moulding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass — so-called fiberglass reinforced plastic (FRP) — are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls.

Unsaturated polyesters are condensation polymers formed by the reaction of polyols (also known as polyhydric alcohols), organic compounds with multiple alcohol or hydroxy functional groups, with saturated or unsaturated dibasic acids. Typical polyols used are glycols such as ethylene glycol; acids used are phthalic acid and maleic acid. Water, a by-product of esterification reactions, is continuously removed, driving the reaction to completion. The use of unsaturated polyesters and additives such as styrene lowers the viscosity of the resin. The initially liquid resin is converted to a solid by cross-linking chains. This is done by creating free radicals at unsaturated bonds, which propagate in a chain reaction to other unsaturated bonds in adjacent molecules, linking them in the process. The initial free radicals are induced by adding a compound that easily decomposes into free radicals. This compound is usually and incorrectly known as the catalyst[citation needed] . Substances used are generally organic peroxides such as benzoyl peroxide or methyl ethyl ketone peroxide.

Polyester resins are thermosetting and, as with other resins, cure exothermically. The use of excessive catalyst can, therefore, cause charring or even ignition during the curing process. Excessive catalyst may also cause the product to fracture or form a rubbery material.

简单来说这种树脂就是单组份靠加催化剂固化的。具有高透的特点。而且只要自然放置气泡就会完全消失(做出来的成品基本是无气泡的)但是主要问题是这种树脂毒性很高。操作时要在通风环境下带手套进行,本人强烈建议若要使用这种树脂要带手套,护目镜防毒面具。

先上一张图来让大家明白下这种树脂的透明度

好了现在进入正题,如何使用这种Polyester resin做蒲公英及更大型的标本。

3.1 运用模块化制造标本

由于蒲公英的特殊性质导致接触到树脂后就不能在进行任何操作。这样的话对于做出个完美的标本是个很大的问题。所以我们要先将蒲公英预成型然后再将整个预成型的蒲公英浇筑成所要的形状。预成型的蒲公英是由树脂覆盖的。在进行最终浇筑时可以随便移动预成型的蒲公英到任意位置。可以根本性解决浇筑过程中蒲公英移位的问题

预成型的方法就是找个比实际要使用模具小的模具。(我这里用的是番茄酱的盒子)等配置好的树脂气泡完全消失后,将模具倒满树脂,一样让蒲公英自然沉降。位置问题可以完全不用担心。如果自然沉降后还有部分蒲公英在外面,就新配些浇筑,直到完全把蒲公英密封。等待完全硬化。

这时就得到了蒲公英模块,请对这个模块进行切削打磨,使其形状为正方体并且大小要尽可能的接近蒲公英的大小(这是我后来得出的经验,由于这个模块是在我发现打磨抛光技术前做的所以就没有切割,这也导致了一些问题)(正方体按我的经验是最合适的形状,大小和植株接近可以避免最终浇筑后的成品出现折射率不同的情况)

然后进行最终浇筑

用透明胶对模具进行清尘处理

先将模具底层倒上一层薄薄的树脂,然后将预制模具在另一杯用来预浸润的树脂中浸润下。使预制模块底面沾满树脂,(这样可以大幅降低放入预制模块时长生气泡的概率)然后以一定角度缓慢放入模具中,这步一定要多加小心,如果发现预制模块和模具间有气泡就拿起来再放一次 ,等模块到位后,将整个模具填满(由于预制模块偏重,基本不会发生最终浇筑时上浮和移位的情况)将模具盖上...等待一个星期后脱模(一样强烈建议尽可能的久,这种树脂的硬化速度取决于催化剂的量和温度,但还是建议放的尽可能的久)

200字以内,仅用于支线交流,主线讨论请采用回复功能。