A matter of light, Part 3---When to boost and buck-boost By Sameh Sarhan and Chris Richardson, National Semiconductor

In part one of this series, we looked at the basics of LED lighting sources and their driving requirements. In part 2, we discussed why a constant-current buck converter should be your first preference when it comes to switch-mode LED drivers. In this third installment, we investigate larger LED displays and the applications space for other converter topologies.

Manufacturers and designers of LED lighting often refer to applications with clear advantages for solid state illumination as "low-hanging fruit." Examples such as garden path lighting or MR16 bulb replacement often require only a few LEDs, or just one (Fig. 1). The most common voltages for low-voltage lighting are 12 VDC, 24 VDC, and 12 VAC. These applications often use a buck regulator. Although the buck is preferred, as previously discussed, the boost regulator is finding more use as the number of LEDs increase for LED lighting applications. Not content to pick off flashlights or single bulb replacements anymore, designers are targeting large-scale general illumination, systems that require thousands of lumens. Examples include street lighting, residential and commercial lighting, stadium lighting, and decorative or architectural lighting of spaces both interior and exterior.

![37_161_1318073500.jpg]()

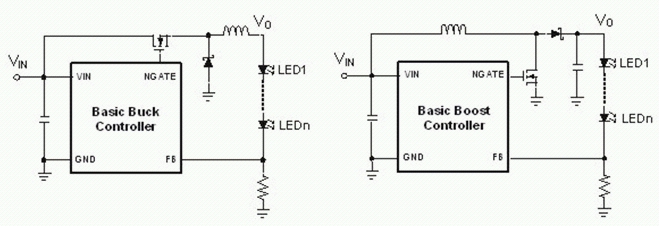

Figure 1: Buck and boost LED drivers with Vocalculation; buck: VO = n x VF, VO VIN。Constant-current still required As with linear and buck-derived LED drivers, the main technical challenge in boost LED driver design is providing a controlled forward current, IF, to each LED of the array. Ideally every LED would be placed in a single series chain, ensuring that the same current flows through each device. A boost regulator is the simplest choice when stepping up a DC input voltage up to a higher DC output voltage, as it allows more LEDs to be placed in series from a given input voltage. A system designer for general illumination usually draws line power at 110 VAC or 220 VAC. If power factor correction (PFC), galvanic isolation, and line harmonic filtering aren't required, then single stage, non-isolated switching converters (buck, boost, or various buck-boost topologies) can use the rectified output of AC line voltage and directly drive long strings of series connected LEDs.

In many cases, however, an intermediate DC bus voltage is used, derived from an AC/DC regulator that takes a universal AC input and provides PFC, isolation, and filtering. Besides solving legal requirements, a lower intermediate voltage bus reduces problems with dielectric breakdown, arcing, and improves the safety of service people working with lighting. The European Union leads the world with the strictest legal requirements, including PFC for any lighting over 25 watts. North America and Asia consistently follow Europe's lead, albeit some years later. Safety standards and electrical codes such as UL and CE limit the output voltage of the AC/DC power supply that forms the input of the boost LED driver. Common rails are 12 and 24 volts, and in some cases 48 volts. Rarely are these intermediate bus rails higher than 60 volts, which is the cutoff for DC voltages under UL Class 2.

The boost challenge Boost regulators are more difficult to design than buck regulators, regardless of whether we control the output voltage or the output current. The average inductor current in a continuous conduction mode (CCM) boost converter is equal to the load current (LED current) multiplied by 1/(1 - D), where D is the duty cycle. Boost voltage regulators require design review at the limits of input voltage to ensure correct design of the inductor, especially the peak current rating. A boost LED driver adds a variable output voltage that influences duty cycle and therefore the inductance and current rating of the main inductor. To prevent inductor saturation, the maximum average and peak currents must be evaluated at both VIN-MIN and VO-MAX. For example, over the range of process, drive current, and die temperature, a typical white InGaN LED's VF can vary from 3 to 4 volts. The more LEDs are placed in series, the greater the gap between VO-MIN and VO-MAX.

Unlike the buck regulator with its output inductor, the boost converter has a discontinuous output current. For this reason an output capacitor is required to keep the output voltage (and hence the output current) continuous. Where the output capacitor in a voltage regulator is designed to both filter and hold up the output voltage during load transients, in a current regulator it functions as an AC current filter only. The capacitance is made as low as possible, consistent with maintaining the desired LED ripple current. The lower the output capacitance (which keeps cost and size to a minimum), the faster the converter's response to changes in output current, and consequently the LED's dimming response is better.

Another serious challenge for boost converters is the control loop. Buck regulators are available with voltage mode PWM control, peak current mode PWM control, constant/controlled on-time, and hysteretic control among others. Boost regulators in CCM (with the exception of low-power/portable equipment) are almost universally constrained to peak current mode PWM control, owing to their right-half plane zeroes and the fact that they deliver power to the output when the control switch is off. To design a boost LED driver that controls output current, the control loop must be analyzed using LEDs as the load, a case much different from the typical load of a boost voltage regulator. In peak current mode control, the impedance of the load has a strong effect on both the DC gain and the low-frequency pole of the control-to-output transfer function. For voltage regulators the load impedance is determined by dividing output voltage by output current. LEDs are diodes, with a dynamic resistance. This dynamic resistance can only be determined by plotting the VF versus IF curve and then taking the tangent line to find the slope at the desired forward current. As shown in Fig. 1, the current regulator uses the load itself as a feedback divider to close the control loop. This reduces the DC gain by a factor of (RSNS/ (RSNS + rD)). It is tempting to compensate a boost LED driver with a simple integrator, sacrificing bandwidth for stability. The reality is that many, if not most LED driver applications require dimming. Whether dimming is done by linear adjustment of IF (analog dimming) or by turning the output on and off at high frequency (digital, or PWM dimming) the system requires high bandwidth and fast transient response just as a voltage regulator does.

The buck-boost challenge LEDs for lighting are being adopted much faster than the standards for solid state illumination have developed. A wide variety of input voltages power a wide variety of LEDs. The number of LEDs in series, the type of LEDs, and the variation of VF with both process and die temperature all contribute to a wide range of output voltage. For example, high-end automobiles are converting to LEDs for their daytime running lamps. Three 3-watt white LEDs present a load of about 12 volts at a current of 1 amp. Automotive voltage systems usually require continuous operation over a range of 9 to 16 volts, with an extended range of 6 to 42 volts where performance is reduced but the system can operate without suffering damage. In general, the buck regulator makes the best LED driver, followed by the boost, but neither is appropriate for this case. If a buck-boost regulator must be used, the most difficult decision to make is often which topology to use.

One fundamental difference between buck-boost regulators of any topology and the buck regulator or the boost regulator is that the buck-boosts never connect the input power supply directly to the output. Both the buck and the boost regulator connect VIN to VO (across the inductor and switch/diode) during a portion of their switching cycles, and this direct connection gives them better efficiency. All buck-boost regulators store the entire energy delivered to the load in either a magnetic field (inductor or transformer) or in an electric field (in a capacitor), which results in higher peak currents or higher voltage in the power switches. In particular, evaluation of the converter at the corners of both input voltage and output voltage is necessary because peak switch current occurs at VIN-MIN and VO-MAX, but peak switch voltage occurs at VIN-MAX and VIN-MAX and VO-MAX. In general this means that a buck-boost regulator of a certain output power will be larger and less efficient than a buck or boost regulator of equal output power.

The single inductor buck-boost can be built with the same parts count as a buck regulator or boost regulator, making it attractive from a system cost standpoint. One disadvantage of this topology is that the polarity of Vo is inverted (Figure 2a) or regulated with respect to VIN (Figure 2b). Level-shifting or polarity inverting circuitry must be employed in these converters. Like the boost converter, they have a discontinuous output current, and require an output capacitor to maintain a continuous LED current. The power MOSFET suffers a peak current of IIN plus IF and a peak voltage of VIN plus VO.

![37_161_1167565179.jpg]()

Figure 2: High-side buck-boost (a); low-side buck-boost (b)。Other topologies The SEPIC converter has the advantages of a continuous input current due to the input inductor and positive output voltage. Like the boost and single inductor buck-boost it requires an output capacitor to maintain a smooth LED current. A further advantage of SEPIC converters is that almost any low-side regulator or controller can be configured as a SEPIC without the need of polarity inversion or level shift circuitry.

![37_161_1183996328.jpg]()

Figure 3: SEPIC LED driver。Rarely used in voltage regulation, the Cuk converter has emerged as an LED driver. Input and output currents are continuous. The polarity of the output voltage is reversed, as with the high-side buck-boost, but the output capacitor can be eliminated like the buck converter. The Cuk is the only other practical non-isolated regulator with this ability.

![37_161_1379580809.jpg]()

Figure 4: Cuk regulator。Neither the boost nor the buck-boost regulator is preferred for switching LED drivers, owing to their higher complexity and parts count, lower efficiency (especially for the buck-boosts) and scant choice of control topologies. However, both are 'necessary evils' as LEDs push into more and more lighting applications. In some cases the system architecture can be altered to allow buck or even linear regulator-based LED drivers. Examples include very large light sources, such as street lights, where a hundred or more 1W+ LEDs are required. In general, LEDs for general illumination are working their way from lower to higher power, and in the intermediate arena, such as automotive headlights and small lighting fixtures, boost and buck-boost regulators represent the best choice for constant-current driving.

About the authors Sameh Sarhan is a staff applications engineer for the Medium Voltage/High Voltage Power Management group in Santa Clara, CA. He has been involved with power electronics in various forms since 1998, having worked for FRC Corp. and Vicor Corp. His experience includes the design of hard/soft switching power supplies from a few watts to 600 watts. Sameh received a bachelor's degree in electronics engineering in 1996 from Cairo University (Egypt).

Chris Richardson is an applications engineer in the Power Management Products group, Medium and High Voltage Division. His responsibilities are divided between lab work, bench evaluation of new ICs, written work such as datasheets and applications notes, and training for field engineers and seminars. Since joining National Semiconductor in 2001, Chris has worked mainly on synchronous buck controllers and regulators. In the last three years he has focused on products for the emerging high brightness LED market in the automotive and industrial areas. Chris holds a BSEE from the Virginia Polytechnic Institute and State University.

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX/showArticle.jhtml;jsessionid=YSAFE5VEPYYTUQSNDLOSKH0CJUNN2JVN?articleID=208401290&queryText= ![37_161_1115731350.jpg]()

![37_161_1262210098.jpg]()

![37_161_1126919048.jpg]()

200字以内,仅用于支线交流,主线讨论请采用回复功能。