第二部分:

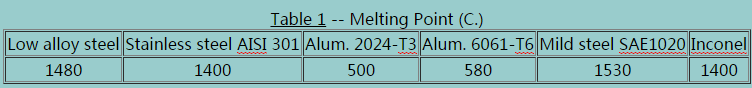

Both the material yield strength and the ultimate strength are similarly affected by elevated temperature. The yield strength (upon which design is typically based for reusable motors) is the stress level, which exceeded, results in permanent deformation, or yielding, of the structure. The ultimate strength is the stress level at which fracture occurs. The effect of elevated temperature on some casing materials is shown in Figures 1 and 2. It can be seen from these figures that aluminum alloys, in particular, suffer significantly even under moderate heating. For example, at 150 C. (300 F.), the 6061 alloy has only about 80% of the room temperature strength. For comparison, low-carbon (mild) steel retains 80% of its yield and ultimate strengths at 240 C. (465 F.) and 380 C. (720 F.), respectively. For reference, melting points are provided in Table 1.

高温下材料的屈服强度和极限强度都会受到影响。超过屈服强度,发动机就会永久变形,超过极限强度,发动机就会裂 (可重用发动机对屈服强度要求很高)。图1图2是高温对几种外壳材料强度的影响。铝合金150多度就开始受不了了,强度都降到80%以下,其他的钢都还好。表格1是各种金属的熔点。

Note that the strength reductions shown are for prolonged exposure (1/2 hour). For very rapid heating, such as that occurs in rocket motors, the effect is somewhat less severe, as illustrated in Figure 3 for 2024-T3 aluminum alloy. Unfortunately, data on rapid-heating strength of most materials does not seem to be readily available. Consequently, the data from Figures 1 and 2 are used for design, which is conservative.

请注意图中的强度减少是加热了半小时得出的数据。在短时间急速加热时,强度减少的不多,就像图3的2024铝合金一样。可惜大部分金属材料没有短时间急速加热的强度数据。因此用图1图2的数据来设计发动机太保守了。

Thermal protection is of particular importance for motors with free-standing propellant grains. Not only are the combustion gases in constant and direct contact with the entire casing walls, more importantly, convection of the gases greatly increases heat transfer to the casing walls.

隔热层对独立式药柱发动机尤其重要。不止是燃气持续的直接接触整个外壁,发动机内的气体流动也会大大增加外壁温度。